Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

5 common mistakes when shrink-wrapping… and how to avoid them

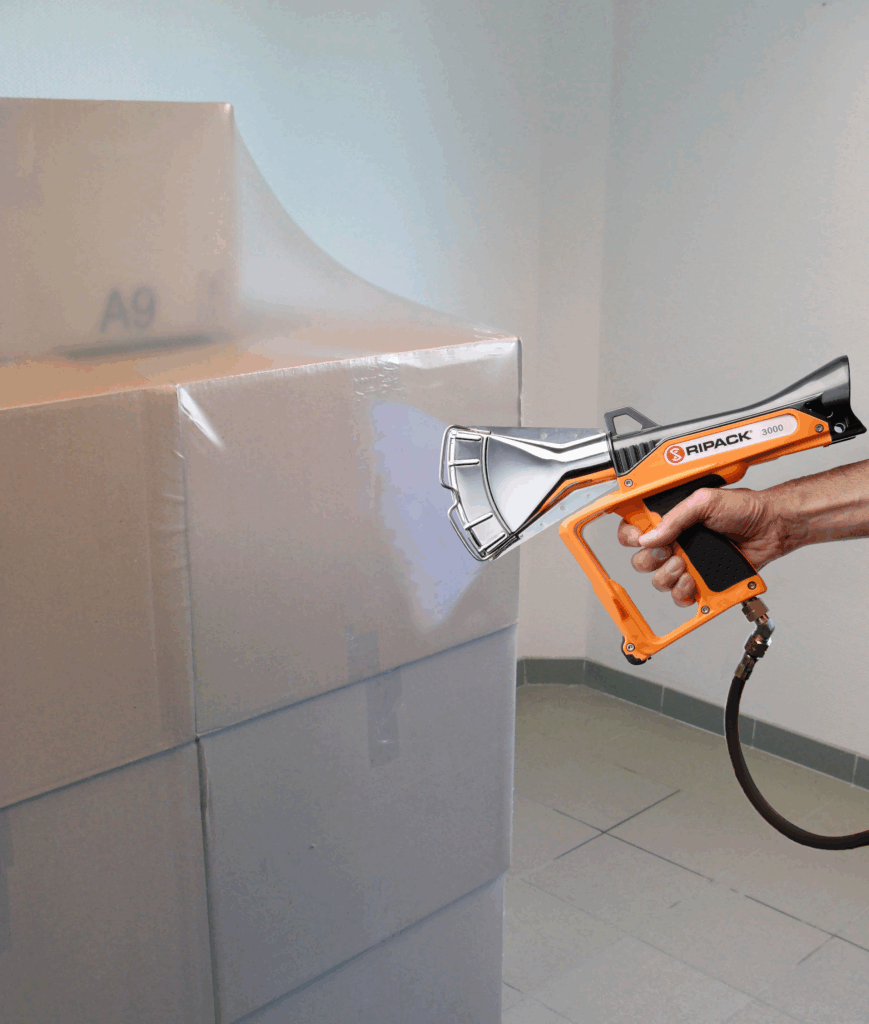

Shrink-wrapping with film is a simple and effective solution to protect pallets, machines, boats or worksites. But like any thermal process, a few bad habits can quickly waste time, damage the film… or even create holes.

Here are 5 very common mistakes we see in the field, and more importantly, how to avoid them.

1. Holding the flame too close to the film

The problem:

When you hold the shrink gun too close to the film, the heat is too concentrated. The result is:

- film that burns through or gets holes,

- overconsumption of film,

- an uneven, unprofessional finish.

How to avoid it:

- Respect the recommended distance (usually around 30 to 40 cm).

- Keep the gun moving continuously, as if you were “sweeping” the surface.

- Always start by heating the thickest areas (corners, folds) instead of insisting on one fixed point.

2. Heating the same area for too long

The problem:

Even at the right distance, staying too long on one spot creates over-thicknesses, burns or holes in the film. You lose quality, strength and time.

How to avoid it:

- Keep moving constantly.

- Work in sections: first the base of the pallet, then the sides, then the top.

- Use a wide back-and-forth motion rather than small, jerky movements.

- Check the overall shrink result before “touching up” details.

3. Using an unsuitable film (too thin, too thick or wrong format)

The problem:

A film that doesn’t match your needs leads to:

- repeated tearing if the film is too thin,

- wasted time shrinking if the film is too thick,

- an unattractive or poorly covered wrap if the size isn’t right.

How to avoid it:

- Define your needs: load weight, storage duration, exposure (indoor / outdoor / sea / UV).

- Adjust the thickness (µm) to the type of application: a light pallet ? a machine exported in a container.

- Choose a cover or sleeve size that matches the real dimensions of the products, to avoid excess material or excessive tension.

4. Not preparing the pallet or the area properly

The problem:

Even with the best shrink gun, a poorly prepared pallet will only give an average result:

- edges sticking out,

- sharp corners piercing the film,

- unstable loads that move during transport.

How to avoid it:

- Check the stability of the load before wrapping (brace if needed).

- Remove or protect sharp edges (corners, metal parts).

- Position the cover or film correctly before starting to shrink, using a pallet riser if necessary.

- Make sure the pallet is accessible all around so the operator can move freely.

In summary

Shrink-wrapping problems are rarely caused by the equipment alone: they usually come from small habits, approximate movements or an unsuitable film. By correcting these 4 points, you improve safety, the final appearance and the overall cost of your operations:

- Flame / film distance

- Heating time on the same spot

- Film selection

- Load preparation

For more information, feel free to contact our team on this page.