L’emballage professionnel est un enjeu majeur pour de nombreux secteurs d’activité. Que vous travailliez dans le négoce de matériaux, l’agroalimentaire, l’industrie ou la logistique, la protection, la sécurisation et la présentation de vos produits nécessitent des solutions fiables et performantes. C’est dans cette optique que Ripack® propose une approche experte de l’emballage, en combinant des […]

Turbopack the heat tools alternative

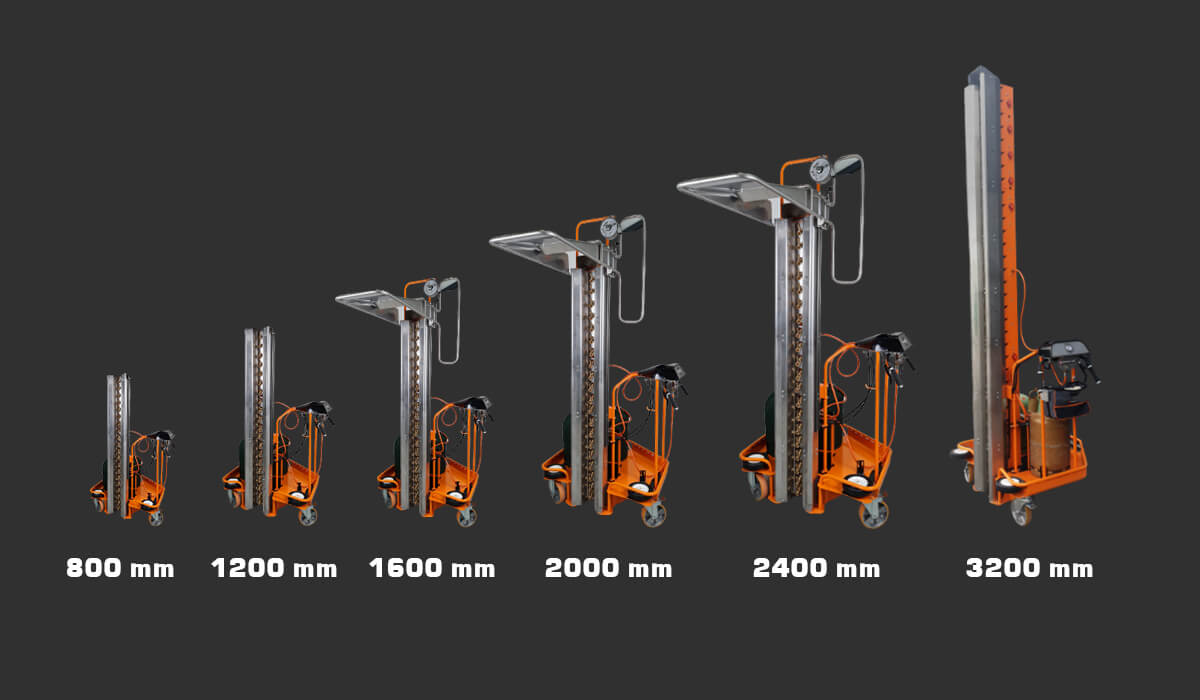

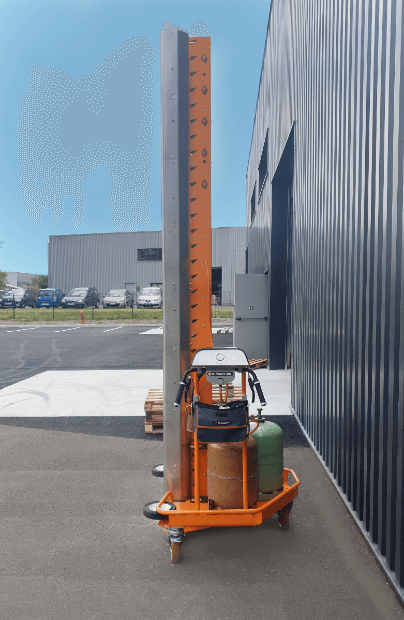

The Turbopack shrinking column is the ideal solution for really significant quantities. Capable of shrinking more than 50 pallets a day, Turbopack is the alternative to Ripack shrink guns and a very expensive automatic line.

Technical table

Find the right solution for your needs

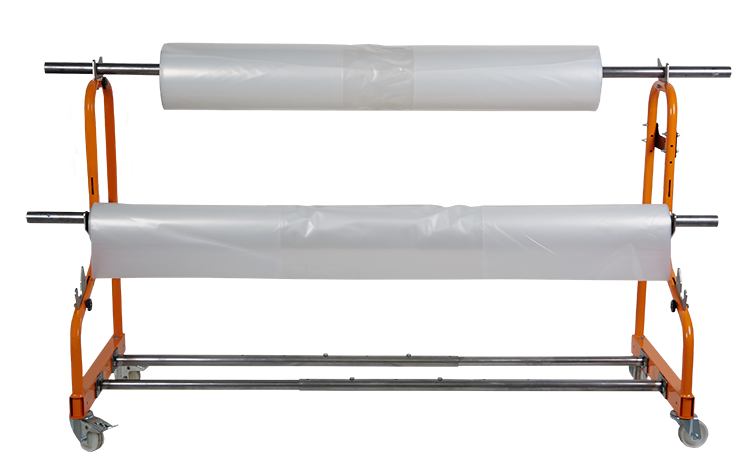

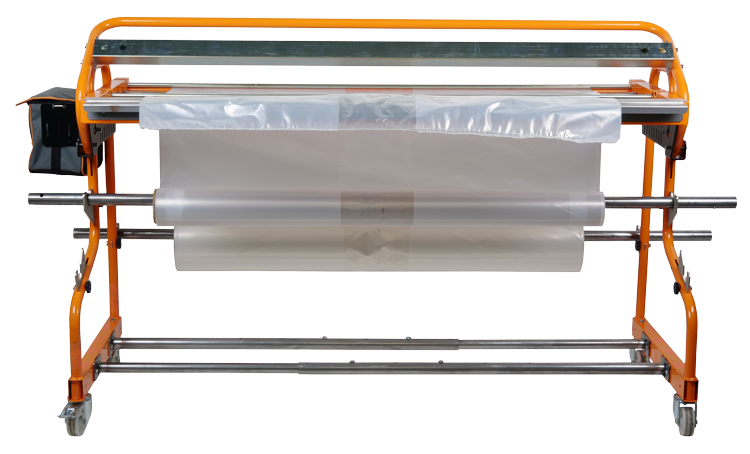

Autonomy and mobility,

the benefits of a mobile shrink station

The Turbopack is a heat shrink column installed on a trolley that is easily moved thanks to its pivoting wheel system. This allows the operator to shrink at any point in the shipping area, thus avoiding the movement of unstable loads.

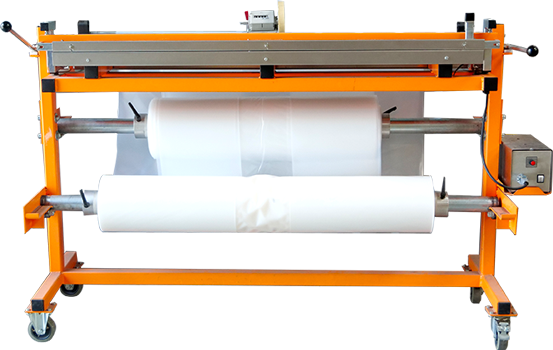

More efficiency thanks to its power and speed

Its unique design allows for a strong hot air flow for efficiency even on thick films. 45 seconds are enough to shrink a pallet (euro type) regardless of the height (upper limit at 3.2 m).

The only adjustment required is to close the valve to set the height to be shrunk. Adaptation to the load to be retracted is therefore quick and easy. There is no need for programming, time-consuming handling or complex maintenance.

Economical and flexible for an unmatched price/performance ratio

The Turbopack can carry up to 3 gas cylinders (13 kg). With more than 60 pallets shrunk per cylinder, the autonomy and low consumption are real assets for your shrinkage station.

There is no limitation of length or width of the load (unlike frames or ovens) and up to 3.20 m high. It is a real advantage for very long pallets and shrinkage of different sized pallets. In addition, a visor option is available for models from 1.6 to 2.4m

More power under full safety with our mobile shrink column

A safety device prevents it from getting unintentionally ignited by blocking the ignition handle. A two-step ignition process ensures the shrinking station is safe.

The design of the control handle means the gas supply is automatically cut off when the control handle is released.