Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

Turbopack: The revolutionary solution for shrinking pallets

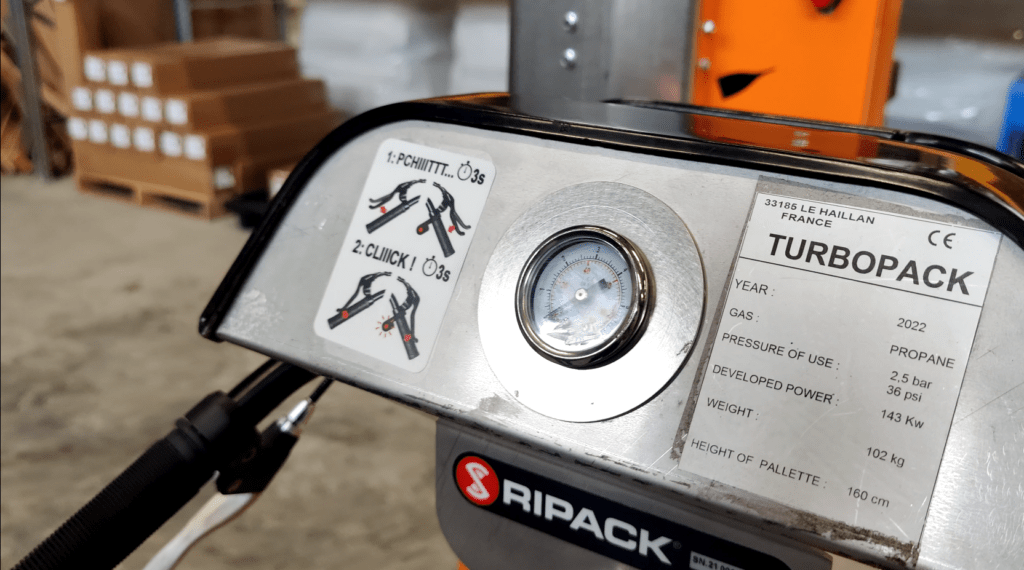

The Turbopack, our mobile shrink column, is an innovation in pallet shrinkage, offering a mobile, efficient and safe solution. This device enables the operator to shrink loads anywhere in the shipping area, avoiding the need to move unstable loads.

Unlike fixed systems requiring peripheral investments such as fixed feeders or conveyors, the Turbopack does not require any of this equipment. There are no limitations in terms of load length or width, and it can shrink-wrap goods up to 3.20 metres high. This flexibility makes it an ideal choice for very long pallets or pallets of various sizes.

The Turbopack can carry up to three 13 kg gas cylinders, offering exceptional autonomy with more than 60 pallets retracted per cylinder. Its low consumption and autonomy are major advantages. With no limits on load length or width, and a maximum height of 3.20 metres, the Turbopack can be adapted to a variety of pallet types. A visor option is available for models from 1.6 to 2.4 metres.

Safety at the heart of Turbopack design

A safety device locks the ignition handle to prevent unwanted ignition. A two-stage ignition procedure makes the retraction station even safer. The design of the control handle allows the gas supply to be switched off automatically in the event of release, and safety valves on each cylinder detect hose rupture. The trolley’s guide wheels avoid contact with the load to be shrunk, ensuring safe operation.

We recently modified the ignition system, which now features a battery-powered electronic piezo. Note that a rechargeable battery may be less efficient. The ignition button, which emits a noise over 3 seconds, makes switching on the Turbopack quick and easy.

Our different models

The Turbopack is available in several models to meet different pallet shrinking requirements, each with its own specific technical features. All models have a clearance of 1400 mm around the pallet and an adjustable pressure between 1.5 and 2.5 bars.

The different heights available are 800 mm, 1200 mm, 1600 mm, 2000 mm, 2400 mm and 3200 mm. Each model is designed to provide total protection and perfect shrinkage thanks to a mobile heating column mounted on an easily movable trolley, enabling loads to be shrunk anywhere in the shipping area, thus avoiding the movement of unstable loads.

Turbopack models differ in terms of energy and gas consumption. For example, the 800 mm model develops an energy of 75 kW with a consumption of 5.48 kg/h, while the 3200 mm model offers an energy of 280 kW with a consumption of 20 kg/h. The empty weight of the models also varies, ranging from 84 kg for the 800 mm model to 140 kg for the 3200 mm model. Some models include a visor option for even more precise adaptation to the loads to be retracted. The 1600 mm, 2000 mm and 2400 mm models have this option, while the other models do not.

Turbopacks are designed for unrivalled efficiency thanks to a hot air flow thrust, enabling rapid retraction in 45 seconds for a Euro pallet, whatever its height. Safety is also a priority, with a double handle system that cuts off the gas supply in the event of release, safety valves on each cylinder to detect pressure faults, and guide wheels to ensure the right distance from the load to be shrunk.

The Turbopack is the ideal solution for companies with high production rates, in excess of 50 pallets a day. It is positioned as an alternative to Ripack® shrink guns and costly automatic lines, offering unrivalled value for money. A pallet is shrunk in 45 seconds.