Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

Turbopack the powerful alternative to traditional heat shrink guns

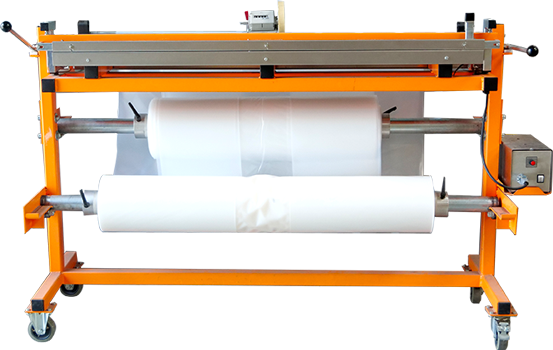

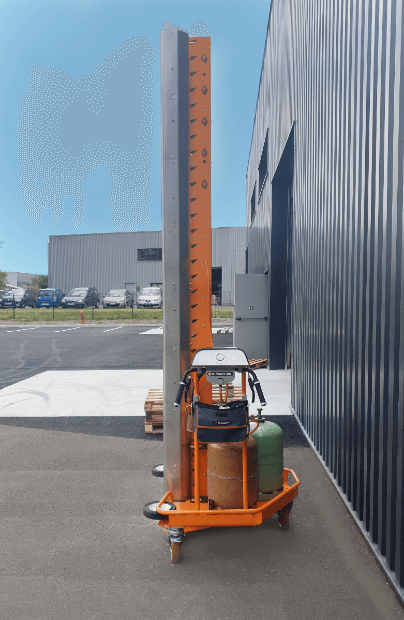

When shipping volumes exceed 50 pallets per day, it’s essential to rethink your shrink-wrapping workstation. The Mobile Shrink Column Turbopack is the ideal solution — a smart compromise between manual heat guns and costly, rigid automatic shrink lines.

Thanks to its clever design, the Turbopack Mobile Shrink Column offers exceptional working autonomy and high performance, all in a compact, mobile, and secure format with minimal floor space requirements.

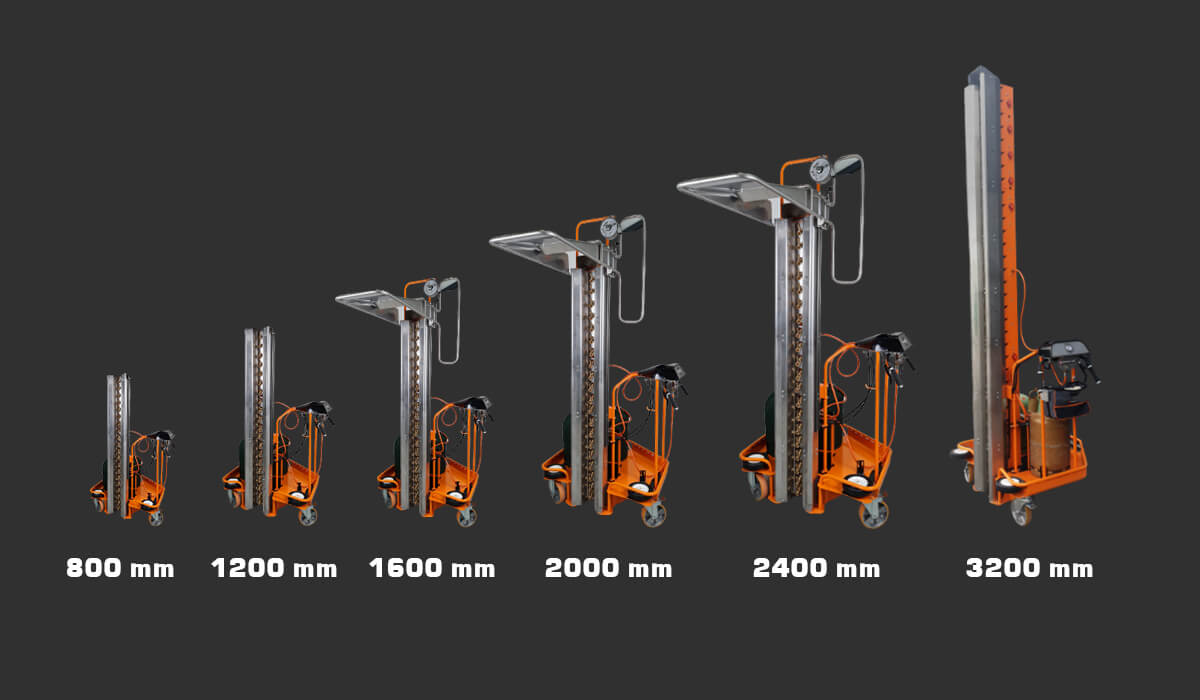

Find the right solution for your needs

Autonomy and mobility,

the benefits of a mobile shrink station

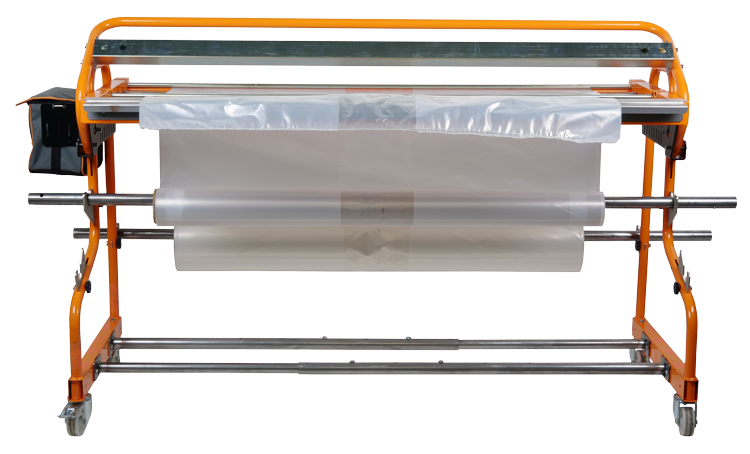

Mounted on a cart equipped with swivel casters, the Mobile Shrink Column Turbopack can be effortlessly moved throughout the shipping area. The operator can shrink-wrap pallets directly at their location, eliminating the need to handle or transport unstable loads.

This high level of mobility not only saves time but also reduces the logistical risks associated with moving unwrapped pallets within the facility.

More efficiency thanks to its power and speed

With its powerful heating system, Turbopack can shrink-wrap a standard euro pallet in just 45 seconds, regardless of height (up to 3.20 meters). The Mobile Shrink Column quickly adjusts to any load: simply set the heating height using the barrier valve and, if needed, adjust the optional guiding slider — no complex programming or tedious setup required.

It is highly effective even with thick shrink films, ensuring a uniform, strong shrink. Power and speed of movement can be adjusted depending on the film and load type.

Economical and flexible for an unmatched price/performance ratio

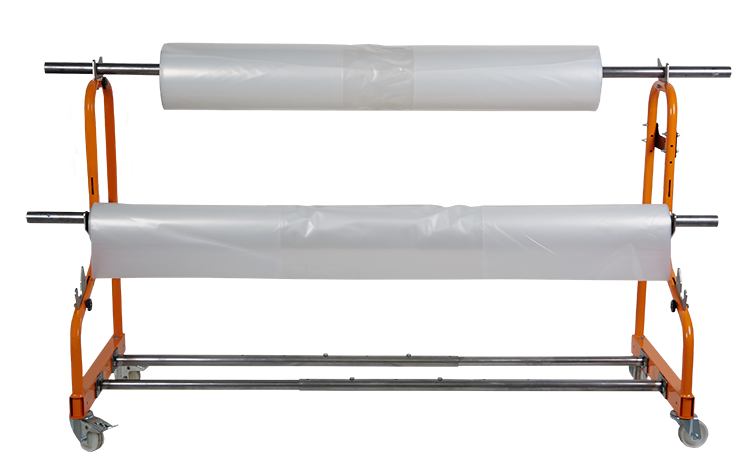

The Mobile Shrink Column Turbopack can carry up to three 13-kg gas cylinders, providing over 294 shrink-wrapped pallets of autonomy. With more than 95 pallets per bottle, it combines energy efficiency with cost-effective operation, without compromising the quality of the final result.

It is perfectly suited for wrapping cubical or irregular goods of various sizes, with no limitations in width or length — a key advantage in demanding industrial environments. It’s the ideal solution for shrink-wrapping pallets, construction modules, tiny houses, and more.

More power under full safety with our mobile shrink column

The Turbopack control system includes multiple safety features: dual ignition procedure, anti-trigger safety handle, and automatic gas shutoff if the handle is released.

This ensures the Mobile Shrink Column remains a powerful yet entirely safe tool to operate — combining high heat output with total control and operator protection.