Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

GESTURES AND POSTURE ON THE PACKING STATION

Gestures and good postures on the packing station

As a packaging professional, it is essential to think about the right layout for your workstation. Once you have defined your areas to avoid clutter, you will need to think about the packing station itself. Ergonomics is the key word here. Indeed, your operators must be able to work in complete safety, in order to adopt the right gestures and postures on the packing station.

What facilities are available for the packing station?

In order to avoid any bad posture, the main factor to take into account will be the layout of the elements you will need.

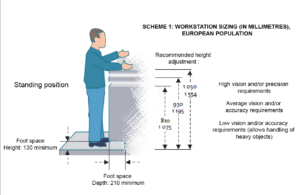

Initially, it will be important to place your packing tables at a height of between 81 and 105 centimeters (see image). Ideally, you should have an adjustable table, so that each operator can adapt it to his or her size.

Workstation sizing, Institut National de Recherche et de Sécurité (French National Institute for Research and Safety)

Also, take care to place at disposal all the indispensable elements for packaging (labels, cardboard boxes, adhesive tapes, etc.). This will enable the operator to avoid any awkward posture such as a bent back, arms outstretched or raised, twisting or bending.

In a second step, in order to be optimized, your packing station will have to be composed of a table, shelves containing the necessary material, adjustable bars, as well as a trash can.

Your packing station will therefore offer maximum ergonomics, will ensure operator comfort, efficiency and speed, and will avoid any musculoskeletal disorders (MSD).

What are MSDs?

The term MSD is a common term when talking about postures at work. It is a group of diseases located in the joints of the wrist, elbows, shoulders, spine or knees.

The symptoms of these diseases can be pain, heaviness or stiffness. These are divided into 3 levels:

- Level 1 : complaints appear during activity, and disappear at rest,

- Level 2 : complaints appear quickly during activity, and take longer to disappear at rest,

- Level 3: complaints such as pain, heaviness or stiffness are chronic and persist during other activities and at rest.

There are three risk factors for MSDs that need to be considered:

- According to the Ministry of Labor, there are biochemical factors:

- Posture, outside the comfort zone, can lead to stretching or compression of structures

- Strength, intensity of force, type of muscle contraction, joint position and grip distance, grip, characteristics of the object being lifted,

- Repetition,

- The duration of the activity

The combination of these four parameters leads to a higher risk of developing musculoskeletal disorders.

- Environmental factors:

The biochemical stresses described in the previous paragraph may be aggravated by the presence of environmental factors, such as mechanical pressures produced by contact of the body with external objects, shocks, vibrations, quality of lighting or cold.

- Organizational factors

Poor working conditions play a role in the emergence of musculoskeletal disorders in employees. Elements related to the possibility of control, clarity of task, interpersonal relations, and time constraints or imposed pace are among the factors identified.

All these factors are important to consider when you set up and organize your packing station. If you have any questions, please do not hesitate to contact us via the contact form, we will put you in touch with specialized experts/suppliers.