Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

THE HISTORY OF RIPPES

The history of Maurice Rippes.

The Rippes brand was created by Maurice Rippes, born in 1885 in Bordeaux (France). At the age of 12, he was placed in an apprenticeship with Mr Champs, a plumber in Bordeaux, where he learned the trade and the love of a job well done.

Maurice Rippes married Adrienne Courrege in 1909, and was sent to the front in 1914 as a reservist, where he was wounded. After his discharge, he was assigned to a mechanical workshop in Ales, Gard (France), where he learned the use of machine tools. He was demobilized in 1919, and hired as a turner at the Ledoux company, manufacturer of air-gas flashlights.

Mr Champs, with whom Maurice Rippes had done his apprenticeship, died in 1920, and left him the plumbing business. In 1922, Maurice Rippes patented an automatic valve for hot water dispenser and built copper bath heaters, precursor of instantaneous water heaters. He named his bath heater “Le Gaulois” in homage to Vercingetorix.

The beginning of the Rippes workshops.

At the same time, dissatisfied with the soldering lamps of all brands that he used because of the yellowish flames that deposited carbon on the lead, he designed and patented the “block burner” that ensured good gasification of the gasoline and a flame that was always blue, in all positions: gasification in a baffle, angled needle valve. He adapted his burner to existing welding lamps.

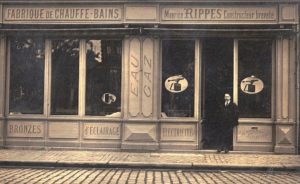

In 1923, the workshop became the “Fabrique de chauffe-bain et de lampes à souder”.

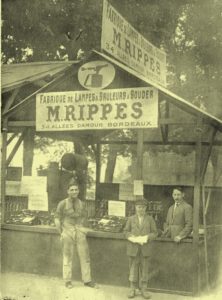

Maurice Rippes exhibited at the Bordeaux Fair in 1923.

The growing success of the soldering lamp.

Between 1935 and 1938, the exhibitions follow one another, and the range grows.

Soldering lamp n°22 – ½ liter pump with anti-backflow device.

Soldering lamp n°44 – 2 liters.

Various special devices are created, always with “block burner”.

Product evolutions.

The Rippes products have evolved, and each device is now equipped with a finned cap for filling, as well as a safety valve. The lead safety cap disappeared.

This change marks the appearance of new models of lamps, less in demand.

- Hot marks with one or two burners depending on the size of the stamp

- Leak detector lamp for ethyl chloride, a colorless liquid used in refrigerators.

- Lamp with a tapered flame for the soldering of battery terminals

- Vertical burner heating lamp n°13 – 1 liter

- Soldering iron n°5

Maurice Rippes had a succession of exhibitions, and the block burner lamp was always a success. The representation to wholesalers is done by multi-card sales representatives. A serious implantation is made on the southern half of France. The Gaz de France, the PTT, the shipyards are customers. The workshop now includes 6 companions, and produces each year approximately 2500 devices.

1939: The Second World War broke out; France was invaded by Germany. After the signing of the armistice on June 22, 1940, Bordeaux found itself in the occupied zone, as did the entire Atlantic coast of the country. France had to provide for the maintenance of the occupying army, while the entire economy of the Southwest was deprived of the raw materials essential to production.

Maurice RIPPES was approached by the occupying forces but refused to work for them under various pretexts such as the lack of materials or the fact that the personnel were prisoners.

The post-war period.

After the war, Maurice RIPPES no longer had a raw material allocation, a direct consequence of his refusal to collaborate. The “block burners” were made from whatever was available: steel for the tanks, aluminum for the filling plugs. However, the reserves were quickly exhausted and the company hardly supplied any new material and mainly dealt with repairs of the brand’s appliances.

The wholesale clientele went to the competition.

In 1945, Maurice Rippes is 60 years old, has no children and no apprentice while the company is financially exhausted.

Three years later, Claude Courrège joined the company and learned the manufacturing process on the job.

The company had to adapt: manufacturing was rationalized, the famous “block burners” were now made by stamping instead of sand casting, the operating button was made from a recessed nut. The workshop is equipped with new materials, relaunches the prospecting with the administrations and participates in fairs and develops propane and butane air-gas appliances.

Production finally reached its pre-war level in 1953.

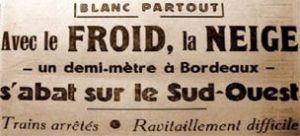

Better still, the record cold weather in Bordeaux in February 1956 caused sales of welding lamps to soar (9 months of welding production recorded in 2 weeks).

Later in the same year, the special P.T.T. model is created in collaboration with the P.T.T. services in Paris. It is a 0.5-liter lamp model with a pump incorporated in a vertical brass handle.

Shortly after, on January 9, 1957, Maurice Rippes died. He will not know the decline of the gasoline lamp, which had made his pride rightly.

Mr. Maurice RIPPES, born in Bordeaux, in the St Bruno district, lived, worked, died and was buried in the same district, which is quite rare nowadays.

Mr. Courrège’ takeover and the decline of the gasoline soldering lamp.

After the death of Mr. Rippes, Claude Courrèges took over the company and oriented the production on air-propane flashlights.

A collaboration with the LEJEUNE company (barrel 75) for the supply of 45 cl lamp bodies will ensure a small production until 1966, date at which was stopped all manufacture of gasoline appliances Mr. RIPPES.

The company will continue on other productions, but this is another story.