Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

A system unique in the world

SEFMAT’s ability to develop innovative, secure products has enabled it to create several brands operating in different markets.

The RIPACK® brand specializes in packaging, RIPAMARK® in road marking, RIPACK SUPPLIES® in the protection of bulky industrial goods, and RIPAGREEN® in thermal weed control.

What all these brands have in common is a patented technology that is unique in the world, enabling the production of hot air over a significant width, with unrivalled levels of safety.

The experience acquired over almost 100 years is the Group’s guarantee of product reliability and expertise.

Our vision remains unchanged: constant innovation to meet our customers’ expectations.

IN THE WORLD

Quality & safety Our customers' safety is at the heart of our innovations

Our patented “cold nozzle” technology, for example, prevents contact burns on our RIPACK range of guns. The technology integrated into our double-safety regulators protects the operator during use of our products.

Our commitment to quality in manufacturing is also a commitment to the safety of our users. To guarantee this level of quality and safety, we comply with the most stringent certifications (UL, ULc, GS, DVGW, CE).

Finally, our warranty levels reflect our ongoing quest for reliability and robustness, with terms ranging from 1 to 10 years depending on the product and brand.

Our values

Innovation

Innovation is at the heart of our development. From the creation of new products and services, to the continuous improvement of our products, we are constantly working on behalf of our customers.

We also innovate in our means of communication, training and assistance to serve you better.

Finally, innovation is also reflected in our management methods, our tools for assisting our teams in dealing with problems and monitoring their resolution.

Quality

Our standards are in line with your expectations. Every day, we implement new mechanisms to improve our products, services and customer experience. By listening to your feedback, we strive to build a relationship of trust based on quality.

The quality of our communication is also an important issue for us. The quality of our relations with our teams, our stakeholders and, of course, our customers is essential to SEFMAT.

Respect

Respect is an essential value that we work on every day with all our stakeholders.

Being able to support our suppliers, help our teams grow and give our best to our customers is what motivates us every day.

Respect takes many forms at SEFMAT

Respect for people

A company’s social role goes far beyond its economic one. Every day, we interact with our customers, suppliers and teams.

We do our utmost to ensure that these relationships take place under the best possible conditions, and are open to improving them.

Within the SEFMAT Group, we focus on 3 main areas:

- training to enable our teams to grow and be supported as the company changes. Our training courses cover a wide range of subjects, from technical skills acquisition to personal development and risk management.

- the search for meaning in all our actions. Closely linked to training, this enables each employee to be a driving force behind the implementation of cross-functional initiatives within the company.

- Team spirit, which can’t be decreed and has to be worked on every day. This allows us to work in a friendly environment, enabling everyone to achieve their full potential and take the time to understand each other.

Respect for the environment

As mentioned above, the meaning we give to our actions is essential if everyone is to identify with our values.

Protecting our environment must be the keystones of this sense of purpose. We take action right from the design stage, with our choice of suppliers, materials and packaging methods. We reduce our waste as much as possible, and if this is not possible, we favor recyclable materials.

We communicate on innovations in plastic recycling, the use of biosourced gases and the reduction of film consumption.

Our responsibility also lies in the information we provide to our customers.

Last but not least, we have set up a number of in-house initiatives that have a direct impact on our immediate environment (i.e. composting, a company vegetable garden, sorting and recycling waste from our refectory and industrial zone).

The small actions of each and every one of our employees, customers and suppliers reinforce our conviction to go further for our planet.

Sustainable development Our commitment to sustainability

A word from our Managing Director, Julien Marigot :

“Can we continue to develop our businesses without integrating, as coherently as possible, a sustainable development or more generally “ecological” strategy? Personally, I don’t think so, or should I say I don’t think so any more (and thanks to my comrades at the CJD (Centre des Jeunes Dirigeant-e-s d’entreprise) for this realization).

There are many reasons to make this shift, but one of them is the meaning you give to your actions, and how they align with your own values. How can you combine making an effort every day at home and not integrating this approach into your business? With the impact this can have? For our teams, our customers, our suppliers?

Without judging or lecturing, we at SEFMAT have chosen to work via different channels. Each action makes the next coherent, starting internally, with small steps, without falling into systematic communication, without going for greenwashing, which is rather “tempting”. Our teams expect realistic actions that are also in line with their own values.

Secondly, we rethink our development model, and that’s when everything makes sense. Don’t shy away from this responsibility, and take the plunge by including the variable “environmental impact” in your list as the starting point for every product or service development. A kind of green veto, to put it nicely…

If, in addition to this, we could use today’s gains, without hiding the fact that these gains sometimes depend on “polluting” solutions to accompany responsible projects.

In this respect, after careful consideration, we have decided to invest in “Team for the Planet”*. Not to hide behind this, but to remain consistent with our global approach.

* a not-for-profit company that creates and finances companies fighting climate change on a global scale

History A know-howforged by experience

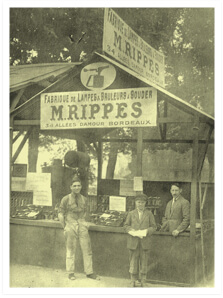

1922

RIPPES production facilities, innovation at the heart of development

Since its creation in 1922, RIPPES production facilities have specialised in designing sealing equipment and have based their success on innovation. A number of patents were filed enabling safer products that use less gas to come onto the market.

Around 1975, RIPPES came up with and developed the idea of covering a palletised load in a cover made from heat shrinkable plastic in order to stabilise the load and protect it from theft and bad weather.

Its mastery of the flame, resulting from this extensive know-how, later led to the creation of the company SEFMAT and its brand, RIPACK.

1975

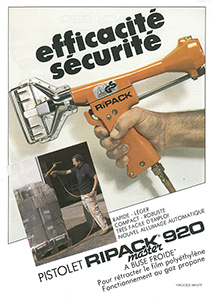

Shrink-wrap begins to be manufactured

SEFMAT was one of the first manufacturers to develop a gas-fed “gun” intended for shrinking heat shrink covers thanks to the heat generated by the hot air produced. From the outset, the SEFMAT has concentrated on innovation in the safety of its equipment and its reliability.

The “cold nozzle” patent which removes any risk of contact burns has enabled RIPACK to become the leading brand on the market worldwide.

2000

Ripack, the leading

brand worldwide

Very quickly, the SEFMAT found outlets for the RIPACK range all over the world. Now, present in more than 140 countries, the RIPACK network is the most extensive in the market.

The quality of our products is inked to the quality of our service, which is why SEFMAT is committed to its international network providing a local service.

2006

A range of extensions

unique in the world

Ripack is the first brand to develop a “combo” extension system. This system allows 2 extensions to be nested, without tools, to form a longer one. Thanks to this development, our brand has established itself in the world of boat wintering and the protection of industrial goods under shrink wrap.

2012

Innovating for the customer

In 2012, the Ripack 3000 model was developed. It will include a quick igniter change system (no tools required) with on-board spare parts. This revolution allows the customer to change his igniter in a few seconds, even during an outdoor work site.

2021

Expanding the range

Ripack2100 and Ripack2500 shrink guns launch. The Ripack 2500 is the lightest gun in its category. The Ripack2100 is ideal for occasional use.