Storing gas cylinders in the workplace is a critical issue for many sectors, including industry, logistics, production, maintenance and packaging. Poor management can lead to serious risks for people, buildings and goods. That is why it is essential to follow strict rules and adopt appropriate practices. At RIPACK, specialists in industrial shrink-wrapping solutions, we support […]

Shrink covers for palletizing

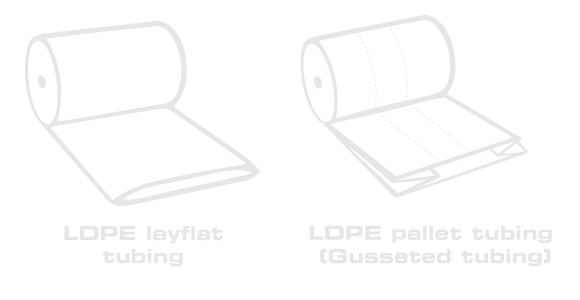

All types of shrink covers are directly shaped from flat LDPE tubing or gusseted LDPE pallet sleeves. Designed to fit various pallet sizes (80 x 120 / 100 x 120), they save you valuable time during packaging operations.

When combined with our storage and cutting solutions, you can store up to four different roll widths on our Multicover 935 dispenser. By using our Multicover 955 or Multicover 960 (manual and electric film sealers), you can easily cut your shrink covers to the exact length needed for your application.

When used with Ripack® professional packaging equipment, our shrink covers provide optimal protection for your palletized goods.

Find the right solution for your needs

Our different types of shrink covers

We offer shrink covers in three main formats:

• Individual shrink covers, ready to use directly.

• Pre-cut shrink covers, sealed and rolled onto a cardboard or plastic core. These are easy to separate thanks to perforated tear lines. Each roll contains only one size of pre-cut covers.

This option is ideal when all your pallets are of the same dimensions (L x W x H). For added convenience, we recommend storing them on the Multicover 935 film dispenser.

• Custom-made shrink covers, cut from flat or gusseted tubing and sealed individually using a manual sealer (Multicover 955) paired with one of our shrink guns, or with an electric sealer (Multicover 960).

This method lets you cut and seal each cover to the exact height you need, starting from a roll whose width and thickness match your requirements.

Types of Shrink Covers by Design

• Gusseted shrink covers: These are the most common type of pallet covers. They are designed with side folds (gussets) that align with the short sides of the cover and the pallet, allowing for easy installation.

• English-style shrink covers: These resemble a bag or pouch with a single bottom seal, offering a simplified structure.

Good to know :

The dimensions of your shrink covers should match your pallet sizes, with a perimeter about 10% larger to ease the installation (draping), and a height about 20 cm greater to allow the excess material to be tucked under the pallet and shrunk, raised about 4–5 cm to ensure stability and proper load retention (secure strapping).

A shrink cover that is too large is easier to position over the pallet or load, but the shrinking process will take longer and consume more energy, without necessarily guaranteeing optimal load securing—since film shrinkage has its limits.

On the other hand, a shrink cover that is too tight relative to the pallet will be harder and more time-consuming to apply (especially for tall pallets), but the shrinking process will be faster and more energy efficient.

The thickness of your shrink covers should be selected based on the weight, number, variety, and shape of the loads to be secured on each pallet.

For heavy or tall loads, a thickness of 150 microns is recommended over 100 microns to ensure better resistance and stability

Ripack Find the ideal solution

Whether you are sending one-off items or large quantities on a daily basis, Ripack has the solution to meet your needs for protecting your goods in shrink film. Tell us what you need and we’ll point you in the right direction.

News our latest news

The year coming to an end has been particularly intense for Ripack. More than ever, our teams have been out in the field, close to industry professionals, to connect, learn, showcase our solutions, and support our partners. Driven by the desire to move forward together, this momentum has been the guiding thread of a year […]

Shrink-wrapping with film is a simple and effective solution to protect pallets, machines, boats or worksites. But like any thermal process, a few bad habits can quickly waste time, damage the film… or even create holes. Here are 5 very common mistakes we see in the field, and more importantly, how to avoid them. 1. […]

Un poste de rétraction performant ne dépend pas uniquement du pistolet de rétraction. Pour obtenir un travail plus rapide, plus confortable et surtout plus sûr, il est essentiel de s’équiper des bons accessoires. Chez Ripack®, chaque détail compte pour garantir la performance, la sécurité et la durabilité de vos opérations d’emballage. Découvrez les 3 accessoires […]